Korean retail sales up in spring

According to multiple sources, Korea’s three largest retailers, Lotte, Shinsegae and Hyundai saw their sales increase an average of 87 percent year-over-year during the first weekend of March. This random sample found that sales even slightly surpassed 2019 levels, when there was no Covid-19. Lotte, for example, saw a 9 percent increase, Shinsegae 14 percent and Hyundai 5.3 percent. Revenue was led by affluent customers buying luxury and electronic items after a large proportion of them had not made major expenditures for almost a year. In the lower price segment, new clothing and cosmetics were in high demand.

In Lotte shopping centers, cosmetics sales increased 91 percent, luxury items increased 143 percent, and home appliances and furniture increased 49 percent. Demand for cosmetics under the SKW100,000 or $87.5 threshold was stronger than ever. Consumers bought these more at shopping malls as duty-free stores remained closed and during the dry spring weather, many shoppers increased their use of skin care products. At Shinsegae Shopping Center, sales of luxury items climbed 109.9 percent and home appliances 75.7 percent. Sales of women’s clothing more than doubled. All figures are for the same period last year, the first weekend of March.

Convenience stores have also seen their wine sales increase recently. Many consumers are treating themselves to some luxury at home, as eating and drinking in restaurants is limited or impossible due to the pandemic.

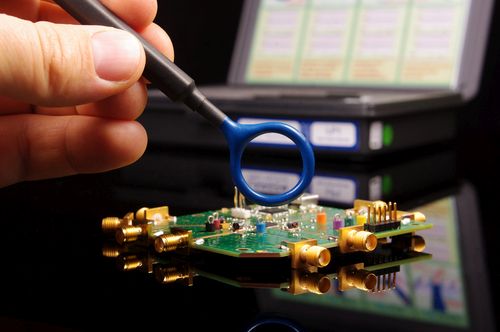

Products made or imported in South Korea require Korea certification before sale. These can be consumer goods such as electronics, but food products also fall under these legal regulations. KC certification, or Korea Certification, is primarily about identifying and containing a potential risk to consumer health and safety. We will be pleased to advise you without obligation regarding a Korea Certification and would be delighted to carry it out for you.

If you need assistance or have any questions regarding Korean certifications like KC, KC EMC, KCs or KCs for explosion safety products, feel free to contact us any time.

Tel.: +49-69-2713769259

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.

Mercedes-Benz and BMW surpass minor Korean automakers

For the first time, Mercedes-Benz and BMW outperformed smaller Korean automakers in sales figures. Therefore, the dominance of Hyundai Motor Group and the two German manufacturers in the South Korean car market continues to increase. According to the Korean Vehicle Import and Distribution Association, the local companies of Mercedes-Benz and BMW each sold 5,707 and 5,660 vehicles, respectively, last month. That represents year-over-year growth of 18.5 percent and 48.5 percent, respectively.

As recently as February 2020, GM Korea was able to sell 5,098 vehicles, while Renault Samsung and Ssang Yong totaled 3,900 and 2,673, respectively. GM Korea was able to surpass both Mercedes-Benz and BMW in sales at the time, but within a year, circumstances changed drastically. The declining sales of Korean automakers began as early as 2018, when foreign brands launched a variety of new models as well as offered attractive discounts. As a result, more and more buyers opted for an imported vehicle. South Korea is currently the largest sales market for the E-Class and 5 Series. Due to the good sales figures, foreign automakers are planning to increase their investment in South Korea to take advantage of the good market situation.

Many products require a certification such as the KC certification in order to be approved for the Korean market. MPR International GmbH will be pleased to advise you on Korea certification in the automotive sector. We have already successfully assisted many large automotive suppliers and vehicle manufacturers with locations in Korea with their certification projects and have been supporting these companies for several years.

If you need assistance or have any questions regarding Korean certifications like KC, KC EMC, KCs or KCs for explosion safety products, feel free to contact us any time.

Tel.: +49-69-2713769259

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.

Korean steel producers confident: Demand and prices on the rise

According to industry sources, Korea’s largest steelmaker Posco has now postponed repair work at its 3rd cold-rolled steel production facility in Gwangyang, South Jeolla Province until April to meet rising demand. The work was originally scheduled for mid-March. Cold-rolled steel is processed with presses at room temperature and has a smooth surface. It is mainly used for vehicles, household appliances and steel pipes. Another company, Hyundai Steel, had also postponed maintenance and repair work earlier this year to ramp up production.

Posco raised prices for hot-rolled steel sheets for the third time, from $72 per ton in January to $89 in February and again in March to $134. Hyundai Steel also plans to raise its prices by $45 per ton. According to the Ministry of Trade, Industry and Energy, the price of iron ore at China’s Qingdao port rose US$10 from earlier this year to US$176 per ton. An anonymous industry official said market conditions for Korean steelmakers have improved due to reduced imports from China. The Chinese economy is recovering faster than predicted from the effects of the Covid 19 pandemic and therefore needs more steel domestically. Steel demand is also stable in other countries as companies steadily recover from the previous economic slump.

Another industry representative said that demand for steel sheets will continue to rise and prices will climb accordingly. He cited higher consumption from the automotive industry and vessel construction as the reason. The trend points to more environmental friendliness: In the automotive industry, more and more new vehicles are being built with electric drivetrains, and gas engines are being used in shipbuilding. An increase in sales of electrical appliances in the domestic and entertainment sectors is also resulting in higher demand for cold- and hot-rolled steel.

Demand for steel and prices could continue to rise. Recently, the Korean government announced plans to build an additional 836,000 housing units by 2025. The price of steel scrap for further processing into flat steel and castings also rose sharply in February. Steel products in South Korea require certification with the KC mark or KC certificate, which is roughly equivalent to the European CE mark and currently applies to 730 different products. MPR International GmbH – Korea Certification is available to answer your questions regarding Korea certification at any time without obligation.

If you need assistance or have any questions regarding Korean certifications like KC, KC EMC, KCs or KCs for explosion safety products, feel free to contact us any time.

Tel.: +49-69-2713769259

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.

New KC EMC Standards to become mandatory in May

The Korean Radio Research Agency (RRA) circulated new standards for KC EMC in their Announcement No. 2021-10 on February 8.

The changes take effect three months after publication and thus the new standards will be mandatory from May 9, 2021.

For KC EMC approvals it means that test reports on the technical requirements for electromagnetic compatibility will have to comply with and show the new standards in order to be accepted.

The following table provides a comparison between the old and new standards:

| Old standards | New standards |

| KN 16-1-1 | KS C 9816-1-1:2020 |

| KN 16-1-2 | KS C 9816-1-2:2020 |

| KN 16-1-3 | KS C 9816-1-3:2017 |

| KN 16-1-4 | KS C 9816-1-4:2020 |

| KN 16-1-5 | KS C 9816-1-5:2020 |

| KN 16-2-1 | KS C 9816-2-1:2020 |

| KN 16-2-2 | KS C 9816-2-2:2020 |

| KN 16-2-3 | KS C 9816-2-3:2020 |

| KN 16-2-4 | KS C 9816-2-4:2017 |

| KN 16-2-5 | KS C 9816-2-5:2020 |

| KN 61000-3-2 / KN 61000-3-12 | KS C 9610-3-2:2020 / KS C 9610-3-12:2020 |

| KN 61000-3-3 / KN 61000-3-11 | KS C 9610-3-3:2020 / KS C 9610-3-11:2017 |

| KN 61000-4-2 | KS C 9610-4-2:2017 |

| KN 61000-4-3 | KS C 9610-4-3:2017 |

| KN 61000-4-4 | KS C 9610-4-4:2020 |

| KN 61000-4-5 | KS C 9610-4-5:2020 |

| KN 61000-4-6 | KS C 9610-4-6:2020 |

| KN 61000-4-8 | KS C 9610-4-8:2017 |

| KN 61000-4-11 | KS C 9610-4-11:2020 |

| KN 61000-4-9 | KS C 9610-4-9:2019 |

| KN 61000-2-2 | KS C 9610-2-2:2017 |

| KN 61000-2-4 | KS C 9610-2-4:2017 |

| KN 11 | KS C 9811:2019 |

| KN 60601-1-2 | KS C IEC 60601-1-2:2007 |

| KN 60974-10 | KS C 9974-10:2020 |

| KN 60255-26 | KS C IEC 60255-26:2020 |

| KN 41 | KS C 9990:2017 |

| KN 301 489-51 | KS C 9995:2021 |

| KN 14-1 | KS C 9814-1:2020 |

| KN 14-2 | KS C 9814-2:2020 |

| KN 15 | KS C 9815:2019 |

| KN 61547 | KS C 9547:2020 |

| KN 60 | KS X 3141:2015 |

| KN 301 489-1 | KS X 3124:2020 |

| KN 301 489-17 | KS X 3126:2020 |

| KN 301 489-52 | KS X 3129:2020 |

| KN 301 489-6 | KS X 3128:2014 |

| KN 301 489-13 | KS X 3131:2014 |

| KN 301 489-5 | KS X 3127:2014 |

| KN 301 489-3 | KS X 3125:2020 |

| KN 301 489-9 | KS X 3130:2014 |

| KN 301 489-50 | KS X 3135:2020 |

| KN 301 489-18 | KS X 3132:2014 |

| KN 301 489-15 | KS X 3136:2014 |

| KN 301 489-2 | KS X 3137:2014 |

| KN 301 489-27 | KS X 3134:2014 |

| KN 301 489-32 | KS X 3138:2015 |

| KN 301 489-20 | KS X 3139:2014 |

| KN 62040-2 | KS C 9040-2:2017 |

| KN 60947 | KS C IEC 60947-1:2017 / KS C IEC 60947-2:2019 / KS C IEC 60947-4-1:2016 |

| KN 32 | KS C 9832:2019 |

| KN 35 | KS C 9835:2019 |

| KN 61800–3 | KS C 9800-3:2017 |

| KN 12015 | KS B 6955:2019 |

| KN 12016 | KS B 6945:2019 |

| KN 17 | KS X 3143:2020 |

| KN 61000-6-3 | KS C 9610-6-3:2017 |

| KN 61000-6-1 | KS C 9610-6-1:2019 |

| KN 61000-6-4 | KS C 9610-6-4:2017 |

| KN 61000-6-2 | KS C 9610-6-2:2019 |

| KN 100 | KS C 9991:2019 |

| KN 101 | KS C 9992:2019 |

| KN 160 | KS C 9993:2019 |

| KN 15194 | KS C 9994:2021 |

If you have products for which a KC EMC registration for electromagnetic compatibility is required we would be happy to support you with the registration under these new standards.

For products with radio technologies, KC EMC certification is also required to gain access to the South Korean market. This applies to products with radio technologies such as Wi-Fi, Bluetooth, RFID or other wireless communication technologies. MPR International GmbH has solid experience in Korea certification and competent local partners.

If you need assistance or have any questions regarding Korean certifications such as KC, KC EMC, KCs or KCs for explosion safety products, feel free to contact us any time.

Tel.: +49-69-2713769259

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.

Hyundai and Kia boost expansion of charging infrastructure for electric vehicles

South Korean carmaker Hyundai Motor Group is accelerating the expansion of its charging infrastructure in preparation for numerous new electric-drive models scheduled for launch this year. Leading the way is the Ioniq 5, which is based on the proprietary EV platform E-GMP and is already eagerly awaited in South Korea as well as Europe. As another electric vehicle manufacturer, Kia has signed a contract with GS Caltex to install charging stations at their gas stations. Drivers of a Kia electric car are to receive further discounts as well as coupons when charging at GS Caltex.

A total of 8 charging stations will be installed under the cooperation: a 350 kW super fast charging station and 7 other 200 kW fast charging stations at four locations in Seoul and nearby cities. GS Caltex is responsible for the operation of the charging stations and plans to commission them before the end of the first half of 2021. The 350 kW superfast charging station is capable of charging the 800-volt technology-based Kia EV6 to 80 percent in just 18 minutes. The new Kia EV6 will be unveiled to the public later this month.

Meanwhile, the Hyundai Group is working to add charging stations to existing gas stations. The goal is to build a network of 120 superfast charging stations at 20 locations this year. The sites are located in major cities and at rest stops along the highway. In terms of electric mobility, Hyundai also has more good news to report. The Ioniq 5, Hyundai’s first model based on the E-GMP platform, has been enthusiastically received by customers and the press. In South Korea, 26,000 vehicles have already been reserved in advance by potential customers. This is almost equivalent to the planned annual sales figures. On the first day of reservations in Europe, 3,000 vehicles were pre-ordered there. Pre-bookings for the Kia EV6 are expected to reach similarly high numbers.

Are you interested in the Korean automotive market? Before your products can be launched on the market there, they must undergo certification. MPR International GmbH will be pleased to advise you regarding a Korea certification in the automotive sector. We have already successfully assisted many large automotive suppliers and vehicle manufacturers with locations in Korea with their certification projects and have been supporting these companies for several years. Our experts are at your disposal at any time by phone or e-mail to answer your questions regarding a pending Korea certification.

If you need assistance or have any questions regarding Korean certifications like KC, KC EMC, KCs or KCs for explosion safety products, feel free to contact us any time.

Tel.: +49-69-2713769259

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.

Korean automotive industry on a solid recovery track

The Ministry of Trade, Industry and Energy released the corresponding figures on February 15. Automobile production increased 24.9 percent, domestic sales increased 18.4 percent and exports increased 24.9 percent. For the first time in five months, all these figures increased by more than 10 percent. In numbers, exports increased from 148,546 to 192,322 units in one year. SUVs in particular increased by 37.7 percent and now account for 71.7 percent of all exported vehicles. Due to the resurgence in demand from the U.S., all categories except compact cars posted increases.

Export volume reached $4 billion in January, up 40.2 percent from a year earlier. That’s the highest figure since September 2017, led by exports of luxury SUVs and environmentally friendly vehicles with alternative engines, whose exports more than doubled. Last month, exported hybrid and electric vehicles from Korea reached a record $900 million. That represents a quarter of the country’s total auto exports.

In the domestic market, a total of 134,692 vehicles were sold in January 2021, including about 22,000 imported cars. Monthly production capacity increased to 314,190 units from 251,578 in the same month last year. This increase represents 24.9 percent and is the best figure since October 2018. Are you interested in the Korean automotive market? Before your products can be launched on the market there, they must undergo a KC certification. MPR International GmbH will be pleased to advise you regarding Korea certification in the automotive sector. We have already successfully assisted many large automotive suppliers and vehicle manufacturers with locations in Korea with their certification projects and have been supporting these companies for several years. Our experts are available at any time by phone or e-mail to answer your questions regarding a pending Korea certification.

If you need assistance or have any questions regarding Korean certifications like KC, KC EMC, KCs or KCs for explosion safety products, feel free to contact us any time.

Tel.: +49-69-2713769259

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.

South Korean Posco Group invests in the safety of its plants

During a visit to a pier for unloading ships inside the steel plant in Pohang, North Gyeongsang Province, Posco CEO Choi Jeong-woo made his own assessment of the safety measures and inspected the facilities together with employees. Unfortunately, an industrial accident occurred there a week earlier, in which a 35-year-old worker was fatally injured. As head of the company in charge of safety, Choi said they would generously compensate the family and fully cooperate with authorities to determine the cause of the accident. Already in the past three years, the group has invested the sum of $904 million in occupational safety measures. “However, there is still much to be improved,” Choi is quoted as saying.

For example, Choi now requires that both subcontractors and Posco employees attend briefings held before maintenance work. In the meetings, called “toolbox” meetings, information about the respective risks of the work process are to be exchanged and discussed. For the safety of its own employees, Posco distributed 1,300 smartwatches to employees in hazardous workplaces last year to monitor their health. This year, another 1,400 smartwatches will be handed out. In addition, about $904 million will be invested in facility safety over the next three years. The funds will go toward replacing and upgrading old pipelines, conveyor belts and similar equipment.

These potentially hazardous machines and equipment require KCs certification in Korea, where the “s” stands for Safety. The mark is issued by the Korea Occupational Safety and Health Agency (KOSHA). Within this certification there are two groups, which differ in the facilities concerned as well as the procedure for certification: the Certification of Compliance (CoC) and the Declaration of Conformity (DoC). MPR International GmbH is at your disposal for any questions about Korea certifications.

If you need assistance or have any questions regarding Korean certifications like KC, KC EMC, KCs or KCs for explosion safety products, feel free to contact us any time.

Tel.: +49-69-2713769259

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.

Posco Chemical builds 4th production facility for cathode base materials

Posco Chemical Co, a subsidiary of South Korean steel giant Posco, mainly produces refractory materials and secondary base materials for batteries. To capitalize on the growing demand for electric car batteries, the company is investing around $249 million in a fourth cathode basic materials production facility. The investment will expand the existing cathode materials factory in Gwangyang, South Jeolla Province, Posco announced at the groundbreaking ceremony in late February. Production is scheduled to start in 2023.

A fourth plant will increase the group’s annual production capacity to 100,000 tons. The expansion will mainly involve the construction of production lines for nickel-containing NCMA cathodes. NCMA cathodes are combined with NCM cathodes and increase the stability of the batteries and their capacity while keeping production costs low. Such a vehicle battery can achieve a range of up to 500 kilometers on a single charge.

Already last year, Posco Chemical started to expand its production for vehicle batteries. The capacity of the plant in Gwangyang was increased to 25,000 metric tons, starting there with 5,000 tons annually. The next increase of another 30,000 tons is already under construction and will start operations in November. The future annual output of 100,000 tons of cathode raw material in 2023 is sufficient for 1.1 million electric cars, each equipped with a 60 kWh battery. Electric car components, which include batteries, must undergo certification for the KC mark or KC certificate in Korea. Our experts are available to answer their questions at any time without obligation.

If you need assistance or have any questions regarding Korean certifications like KC, KC EMC, KCs or KCs for explosion safety products, feel free to contact us any time.

Tel.: +49-69-2713769259

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.

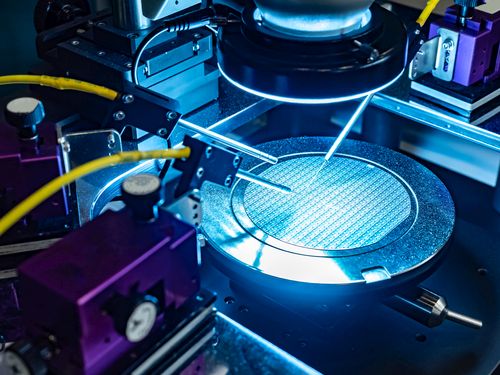

SK continues to invest large sums in the development of computer chips

SK hynix is stepping up its commitment to the semiconductor business to meet the current high global demand of computer chips. As the world’s second largest manufacturer of DRAM memory, the company has signed a $4.3 billion purchase agreement with Dutch machine manufacturer ASML Holding. SK hynix will purchase ASML’s EUV scanners for semiconductor production over a five-year period and integrate them into their production. This step for the expansion of the production numbers at SK hynix takes place in a period which is called “Super Cycle” by experts. During a Super Cycle, the demand of computer chips increases rapidly. By purchasing the advanced machines, the chipmaker can ensure mass production of next-generation chips. Payment for the machines is made in installments over a five-year period.

An EUV beam has a wavelength 14 times smaller than the currently used ArF laser. EUV and ArF are used to engrave transistors on silicon wafers. So far, only Samsung’s TSMC uses this novel technology. Another financial burden SK hynix is facing is the acquisition of Intel’s flash memory business. The first installment of $7 billion must be paid by the end of this year, with the remaining amount due by 2025. So far, it is not known how much SK hynix’s exact investment in the EUV machines will be.However, industry insiders expect at least a three-digit million sum. SK hynix also announced that it would commission a total of up to three EUV equipment manufacturers.The cost for a single plant is approximately 175 million US dollars. The EUV production facility will be integrated into the recently unveiled M16 business plan, which aims to produce next-generation DRAM memory. Some experts expect 20 percent growth in flash memory and 17 percent in DRAM this year. The high demand for smartphones and the construction or expansion of data centers are the reason for this positive development.

South Korea is considered one of the most important and innovative industrial nations in the world. Many products that are imported to South Korea have to be tested and certified in advance. MPR International GmbH recommends itself as a partner for your Korea certification. We will gladly check for you without obligation whether your products are subject to certification and prepare an attractive offer for you.

If you need assistance or have any questions regarding Korean certifications like KC, KC EMC, KCs or KCs for explosion safety products, feel free to contact us any time.

Tel.: +49-69-2713769259

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.

South Korea invests heavily in the development of self-driving cars

South Korea will invest $999 million in self-driving car technology development projects and related infrastructure over the next few years. This was announced by a government spokesperson in mid-January 2021. The investment period extends to 2027, with numerous ministries and institutions participating in the investment. Among those named were the Ministry of Trade, Industry and Energy; the Ministry of Science and Information Technology; the Ministry of Land, Infrastructure and Transport; and the National Police Agency. Together, these institutions plan to fund various projects as well as promote the commercialization of self-driving vehicles.

Domestic automakers and suppliers are also to receive corresponding support from the government if they participate in the projects. According to the Ministry of Transport, the funds will be used mainly for the development of technology and adaptation to global standards in the field of autonomous driving and the interconnection of road infrastructure with the self-driving vehicles. The government plans to have level 4 self-driving cars ready for the market and introduction in 2027. In level 4, a car can drive autonomously under certain circumstances and only needs the intervention of a driver in exceptional situations. In South Korea, Hyundai Mobis Co, the parts supplier of Hyundai Motor Group, has taken the lead in developing technology for use in self-driving cars.

The group plans to integrate Level 3 autonomous driving technology into its vehicles in 2022. Hyundai Mobis, meanwhile, is collaborating with international automakers to develop technology for level 4 and 5 self-driving vehicles. To explain, a level 3 vehicle can independently change lanes and navigate moving traffic when the technology is fully deployed. At Level 5, a vehicle is capable of driving itself under all conditions and without driver intervention. Vehicle components, which include assistance systems for autonomous driving, must undergo certification for the KC mark or KC certificate in Korea. Our experts are always available to answer any questions without obligation.

If you need assistance or have any questions regarding Korean certifications like KC, KC EMC, KCs or KCs for explosion safety products, feel free to contact us any time.

Tel.: +49-69-2713769259

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.