South Korean steel producer POSCO launches first environmentally friendly free-cutting steel

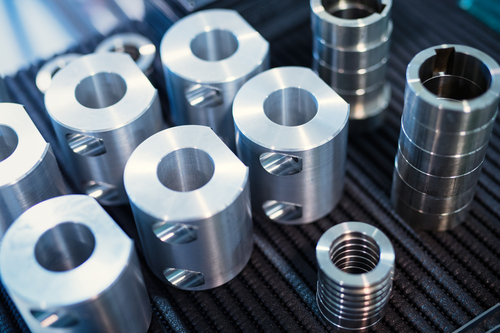

South Korean steelmaker POSCO announced through a press release in August 2020 that the company successfully started mass production of lead-free free cutting steel in June and is now looking for customers in the automotive and IT industries. The new material is called POSCO Graphitic Steel for Machinability (PosGRAM) and is the world’s first graphite-based free cutting steel. Free-cutting steel is often offered as rod-like material and enables fast machining in appropriate machines and cleaner surfaces than conventional steel. It is typically used for metal parts of vehicles and IT products that have complex geometries or have particularly high accuracy requirements.

Current steels of this type often contain lead, which is cheaper than other additives but poses health and environmental problems. During alloying in the steel mill, toxic lead vapors are released from the molten metal and special equipment must be used to extract and capture the vapors. As a result, lead-alloyed free-cutting steels are no longer produced in large quantities. Due to increasing environmental concerns, global standards have been adopted, including by the EU, which reduce the amount of lead in steels to 0.1 percent. However, since no adequate substitutes for lead have yet been found for free-cutting steel, up to 0.35 percent lead is permitted here.

POSCO reiterated the significance of mass production of PosGRAM, which replaces lead with graphite without sacrificing processing speed. PosGRAM has clean and even surfaces in any cutting direction and can be used in electromechanical components because it is easy to magnetize. POSCO has been researching the development of graphite free cutting steel since 2017 and began mass production in 2020. The company has been selling the steel to some customers since June. Annual global demand for free-cutting steel is an estimated 1 million tons, half of which is lead-based products. Previously, there was no company in South Korea producing lead-free free-cutting steel, so they imported an average of 23,000 tons annually from abroad, including Japan. With the new PosGRAM steel, POSCO expects to replace imported steels as far as possible and contribute to the competitiveness of the domestic industry. Steel products in South Korea require certification with the KC mark or KC certificate, which is roughly equivalent to the European CE mark and currently applies to 730 different products. MPR International GmbH – Korea Certification is available to answer your questions regarding Korea certification at any time and without obligation.

If you need assistance or have any questions regarding Korean certifications like KC, KC EMC, KCs or KCs for explosion safety products, feel free to contact us any time.

Tel.: +49-69-2713769259

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.

LG Chem produces new type of battery for Tesla’s electric cars

The share price of South Korea’s LG Chem rose 3.57 percent on Oct. 22, 2020, the day Tesla announced higher profits than the market expected. Industry experts suspect a high impact of the Tesla announcement on LG Chem’s share price. Industry insiders citing the reason as LG Chem’s development of a new battery for electric vehicles, which Tesla unveiled at the so-called “Battery Day” in September 2020 without mentioning the name of the manufacturer or supplier. Meanwhile, LG Chem is preparing for a surge in Tesla’s orders, tripling its cylindrical battery cell production capacity from the current 20 GWh to 60 GWh by 2023.

The speculation that LG Chem will develop a new battery type and become one of Tesla’s main suppliers is based on two reports. On October 21, 2020, Jang Seung-se, vice chairman of LG Chem, reported that his company is working on the development of cylindrical battery cells, which have a fivefold higher energy density and six times more capacity. These specifications exactly match Tesla’s Type 4680 battery, which Tesla CEO Elon Musk unveiled in September. Initially, Tesla wanted to produce the new Type 4680 battery cells itself. Afterwards, however, it turned out that this would exceed Tesla’s current production capacities and that it would also not be possible to build a new production facility within a year.

Tesla estimates that the required quantity of Type 4680 batteries in 2020 will have a capacity of 100 GWh. These could then be installed in around 1.3 million electric cars annually. LG Chem, the world’s largest battery manufacturer, currently has a total annual production capacity of 100 GWh but was able to increase this to 120 GWh by the end of 2020, according to the company. Nearly all of the cylindrical battery cells for electric vehicles that LG Chem produces are installed in Tesla models. In order to supply other manufacturers besides Tesla or to avoid shortages, LG Chem plans to expand its total annual production capacity to 260 GWh by 2023. Electric car components, which include batteries, must undergo certification for the KC mark or KC certificate in Korea. Our experts are always available to answer any questions without obligation.

If you need assistance or have any questions regarding Korean certifications like KC, KC EMC, KCs or KCs for explosion safety products, feel free to contact us any time.

Tel.: +49-69-2713769259

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.

Everyday objects with OLED displays move a step closer

The eye-catcher of the exhibition is the OLED display technology that LG has installed in numerous interior design and everyday objects in the show house. The living of the future can be seen at LG’s Science Park in the South Korean capital Seoul. The technology in the bedroom is particularly innovative. Built into the footboard of the bed is a 55-inch OLED screen that hides discreetly and can be raised automatically. In the background, sensors analyze sleep behavior and quality and show the result every morning. In addition, the user can display other information such as weather, schedule and news. The screen can be adjusted in height depending on the viewing angle, offering an optimal viewing experience from any position.

The LG Display business unit is working on developing the next generation of OLED displays to expand its product range and differentiate itself from the competition. In particular, the company plans to offer screens for use in the home environment. LG OLED displays are narrower than traditional smart TVs or flat-panel displays, plus they don’t require backlighting and use innovative materials that make them more flexible and durable. LG is currently developing OLED screens from 55 to 88 inches, which are only 1 mm narrow. In the showroom, for example, there is a mirror made of an OLED screen on which users can virtually try on new clothes and then order them directly online. The living room of the show house features a curved OLED screen on the ceiling as well as screens that can change their bend or orientation depending on the viewing angle.

Through the exhibition currently taking place, LG hopes to establish strategic partnerships in the B2B sector with construction companies, home appliance manufacturers, furniture and interior design companies. Collaboration is expected to create synergy in the home interior sector and further expand LG’s competitiveness in the display industry. “The new OLED showroom is part of our innovation initiative, in which LG aims to differentiate itself from conventional TV and IT products and expand into new business areas,” said Alex Kwon, head of business development, LG OLED displays division. To be imported or sold in South Korea, electronic devices are subject to KC certification (also called KC Mark). The KC-Mark or KC certificate is roughly equivalent to the European CE mark and applies to 730 different products. KC certification, or Korea Certification, is primarily about identifying and containing a potential risk to consumer health and safety. We will be pleased to advise you on Korea Certification without obligation and to eventually carry it out for you.

If you need assistance or have any questions regarding Korean certifications like KC, KC EMC, KCs or KCs for explosion safety products, feel free to contact us any time.

Tel.: +49-69-2713769259

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.

South Korean telecommunications companies reduce dependence on their core business

The three largest telecom companies in South Korea, SK Telecom (SKT), KT and LG Uplus, are looking for new business areas and growth industries outside their usual core business, the conventional telecom sector. The companies see difficulties in continuing their businesses in the telephony sector successfully in the post-Corona era and the entry into the so-called “Fourth Industrial Revolution”. According to their own statements, the aforementioned companies have already upgraded or supplemented their conventional telephony services with artificial intelligence, Big Data and cloud services.

A spokesperson for the telecom industry confirmed the shift within the companies toward providers of digital services of all kinds, such as online shopping, web and server hosting, streaming and contactless payment processing. For example, SK Telecom recently changed its company name to SKT to reduce the reference to telecommunications. KT (Korea Telecom) calls itself an “AI company” or “digital platform provider” in hopes of attracting more business customers. LG Uplus dropped the word “telecom” from its company name long ago, and its businesses in other areas outside of telephony have shown good growth rates in recent years.

SKT plans to transform itself into a global tech company with growth in media, IT security and commerce. The basis for this is the existing Information and Communications Technology division. Plans call for the new business areas to account for more than 35 percent of sales in the future. This year, the media sector has already posted a 20 percent year-on-year increase in sales. Here, SKT has bought up the provider T-broad and now offers IPTV services. The number of subscribers increased by 129,000 in the previous quarter. SKT is also planning to establish a platform for mobility and positioning services based on its popular T Map system. A strategic partnership with the cab service Uber is under discussion here.

South Korea is considered one of the most important and innovative industrial nations in the world. To gain market access to this highly technological country, products imported into South Korea must be tested and certified. The KC mark or certificate is roughly equivalent to the European CE mark and applies to 730 different products, including many electronic products. For products with a radio module, KC EMC certification is also required. MPR International GmbH has solid experience in Korea certification and competent local partners.

If you need assistance or have any questions regarding Korean certifications like KC, KC EMC, KCs or KCs for explosion safety products, feel free to contact us any time.

Tel.: +49-69-2713769259

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.