South Korean steel producer POSCO launches first environmentally friendly free-cutting steel

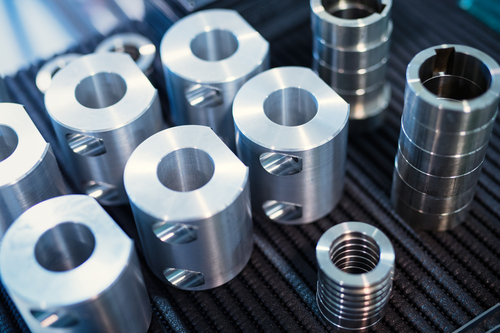

28. January 2021South Korean steelmaker POSCO announced through a press release in August 2020 that the company successfully started mass production of lead-free free cutting steel in June and is now looking for customers in the automotive and IT industries. The new material is called POSCO Graphitic Steel for Machinability (PosGRAM) and is the world’s first graphite-based free cutting steel. Free-cutting steel is often offered as rod-like material and enables fast machining in appropriate machines and cleaner surfaces than conventional steel. It is typically used for metal parts of vehicles and IT products that have complex geometries or have particularly high accuracy requirements.

Current steels of this type often contain lead, which is cheaper than other additives but poses health and environmental problems. During alloying in the steel mill, toxic lead vapors are released from the molten metal and special equipment must be used to extract and capture the vapors. As a result, lead-alloyed free-cutting steels are no longer produced in large quantities. Due to increasing environmental concerns, global standards have been adopted, including by the EU, which reduce the amount of lead in steels to 0.1 percent. However, since no adequate substitutes for lead have yet been found for free-cutting steel, up to 0.35 percent lead is permitted here.

POSCO reiterated the significance of mass production of PosGRAM, which replaces lead with graphite without sacrificing processing speed. PosGRAM has clean and even surfaces in any cutting direction and can be used in electromechanical components because it is easy to magnetize. POSCO has been researching the development of graphite free cutting steel since 2017 and began mass production in 2020. The company has been selling the steel to some customers since June. Annual global demand for free-cutting steel is an estimated 1 million tons, half of which is lead-based products. Previously, there was no company in South Korea producing lead-free free-cutting steel, so they imported an average of 23,000 tons annually from abroad, including Japan. With the new PosGRAM steel, POSCO expects to replace imported steels as far as possible and contribute to the competitiveness of the domestic industry. Steel products in South Korea require certification with the KC mark or KC certificate, which is roughly equivalent to the European CE mark and currently applies to 730 different products. MPR International GmbH – Korea Certification is available to answer your questions regarding Korea certification at any time and without obligation.

If you need assistance or have any questions regarding Korean certifications like KC, KC EMC, KCs or KCs for explosion safety products, feel free to contact us any time.

Tel.: +49-69-2713769259

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.