Bottlenecks in South Korea show importance of foreign machine component imports

4. November 2022

South Korean display machinery manufacturers are suffering from disruptions in the global supply chain, reports The Korea Economic Daily in its online site KED Global. The result of bottlenecks in certain components is delayed deliveries of machines and resulting interruptions in the expansion of production facilities at local panel manufacturers such as global market leader LG Display Co. According to the industry association “Korea Display Industry Association (KDIA),” domestic screen machine manufacturers would not have been able to meet delivery deadlines because important components from other countries were not available. In many cases, technical products must have

KC certification in order to be exported to Korea.

Already known is an extension of the delivery time for OLED screens from three months to now more than six months after order, according to various industry insiders. A South Korean machine manufacturer had to postpone a promised delivery to its customer in June until the end of this year. As a result, the planned expansion of production and replacement of machines at the screen manufacturer was also delayed. Well-known machine manufacturers such as Wonik IPS Co., Jusung Engineering Co. and Sunic System Ltd. failed to procure certain individual parts domestically that are otherwise supplied from overseas. Some manufacturers even had to buy used parts from China for more than double the price.

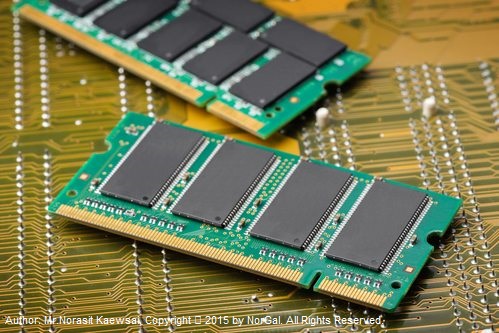

Currently, only 9 percent of all parts needed to make display machines come from South Korea, according to KDIA. Components from the U.S., Japan and Europe account for 37%, 29% and 19%, respectively. For industrial PCs and controls, South Korea relied entirely on suppliers from Taiwan. According to KDIA, such reliance on foreign suppliers makes the domestic industry very vulnerable to disruptions in the global supply chain. The most common components that have to be sourced from abroad are turbopumps, gas and air filters, and o-rings. To avoid such bottlenecks in the future, KDIA plans to work more closely with certain suppliers.

Certifications for the Korean market are a complex hurdle and difficult to navigate due to different authorities and certification systems. With over 15 years of experience in the certification business, MPR International GmbH is your best resource for competent service when it comes to exporting to Korea. For example, KC Safety is relevant for electronics and household products mostly intended for consumers, as well as products for children and babies.

Feel free to contact us any time if you need assistance or have any questions regarding Korean certifications like

KC,

KC EMC,

KCs,

KCs for explosion safety products or

KGS factory registration.

Tel. Europe:

+49-69-271 37 69 261

Tel. US:

+1 773 654-2673

Email:

info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “

Korea Certification Made Easy – The Booklet“.

Already known is an extension of the delivery time for OLED screens from three months to now more than six months after order, according to various industry insiders. A South Korean machine manufacturer had to postpone a promised delivery to its customer in June until the end of this year. As a result, the planned expansion of production and replacement of machines at the screen manufacturer was also delayed. Well-known machine manufacturers such as Wonik IPS Co., Jusung Engineering Co. and Sunic System Ltd. failed to procure certain individual parts domestically that are otherwise supplied from overseas. Some manufacturers even had to buy used parts from China for more than double the price.

Currently, only 9 percent of all parts needed to make display machines come from South Korea, according to KDIA. Components from the U.S., Japan and Europe account for 37%, 29% and 19%, respectively. For industrial PCs and controls, South Korea relied entirely on suppliers from Taiwan. According to KDIA, such reliance on foreign suppliers makes the domestic industry very vulnerable to disruptions in the global supply chain. The most common components that have to be sourced from abroad are turbopumps, gas and air filters, and o-rings. To avoid such bottlenecks in the future, KDIA plans to work more closely with certain suppliers.

Certifications for the Korean market are a complex hurdle and difficult to navigate due to different authorities and certification systems. With over 15 years of experience in the certification business, MPR International GmbH is your best resource for competent service when it comes to exporting to Korea. For example, KC Safety is relevant for electronics and household products mostly intended for consumers, as well as products for children and babies.

Feel free to contact us any time if you need assistance or have any questions regarding Korean certifications like KC, KC EMC, KCs, KCs for explosion safety products or KGS factory registration.

Tel. Europe: +49-69-271 37 69 261

Tel. US: +1 773 654-2673

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.

Already known is an extension of the delivery time for OLED screens from three months to now more than six months after order, according to various industry insiders. A South Korean machine manufacturer had to postpone a promised delivery to its customer in June until the end of this year. As a result, the planned expansion of production and replacement of machines at the screen manufacturer was also delayed. Well-known machine manufacturers such as Wonik IPS Co., Jusung Engineering Co. and Sunic System Ltd. failed to procure certain individual parts domestically that are otherwise supplied from overseas. Some manufacturers even had to buy used parts from China for more than double the price.

Currently, only 9 percent of all parts needed to make display machines come from South Korea, according to KDIA. Components from the U.S., Japan and Europe account for 37%, 29% and 19%, respectively. For industrial PCs and controls, South Korea relied entirely on suppliers from Taiwan. According to KDIA, such reliance on foreign suppliers makes the domestic industry very vulnerable to disruptions in the global supply chain. The most common components that have to be sourced from abroad are turbopumps, gas and air filters, and o-rings. To avoid such bottlenecks in the future, KDIA plans to work more closely with certain suppliers.

Certifications for the Korean market are a complex hurdle and difficult to navigate due to different authorities and certification systems. With over 15 years of experience in the certification business, MPR International GmbH is your best resource for competent service when it comes to exporting to Korea. For example, KC Safety is relevant for electronics and household products mostly intended for consumers, as well as products for children and babies.

Feel free to contact us any time if you need assistance or have any questions regarding Korean certifications like KC, KC EMC, KCs, KCs for explosion safety products or KGS factory registration.

Tel. Europe: +49-69-271 37 69 261

Tel. US: +1 773 654-2673

Email: info@korea-certification.com

Urgent questions?

Please do not hesitate to contact us via chat. You will find the chat window at the bottom right of each page (if this is not visible, please check your browser settings).

For more information you can download our free brochure “Korea Certification Made Easy – The Booklet“.